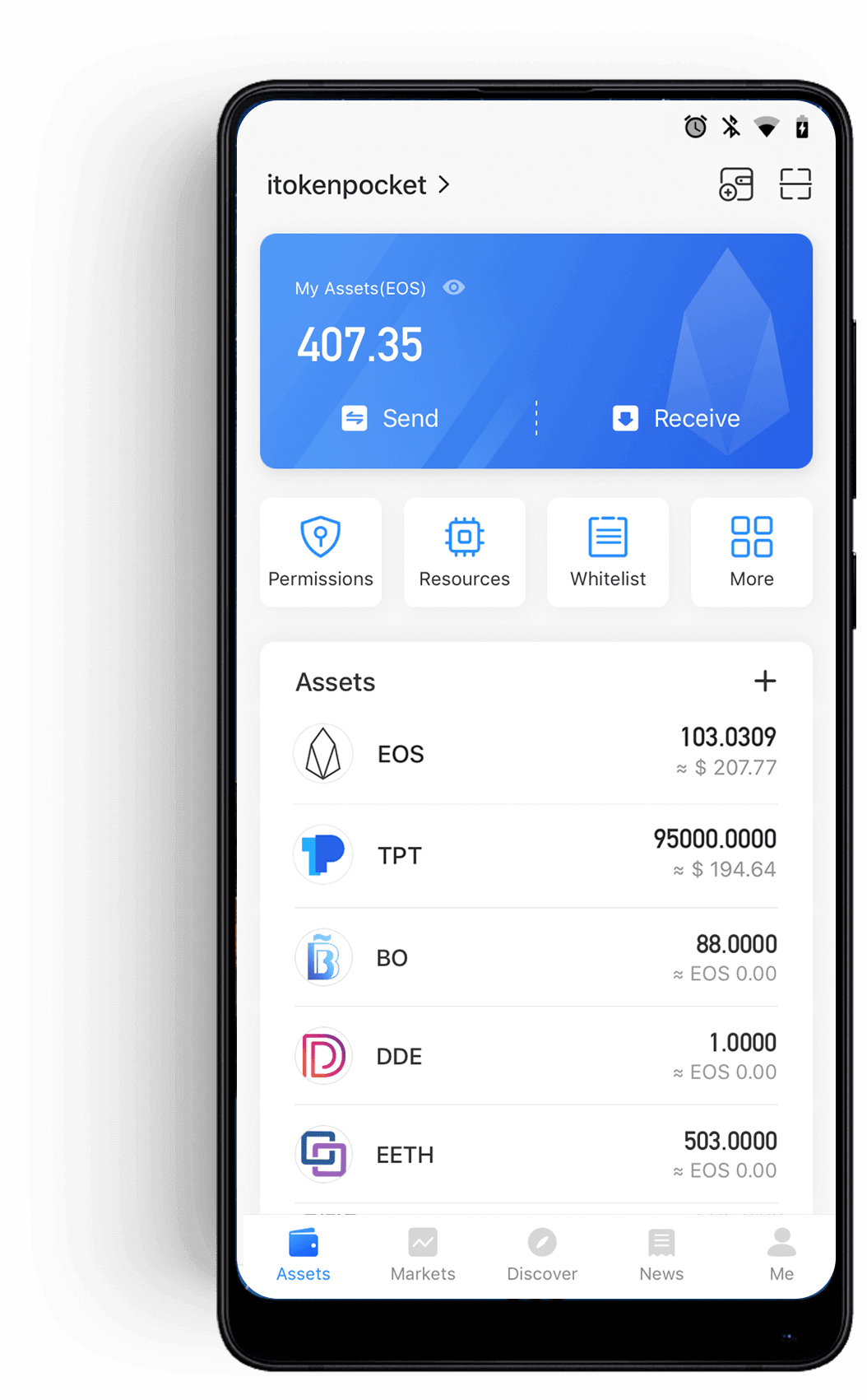

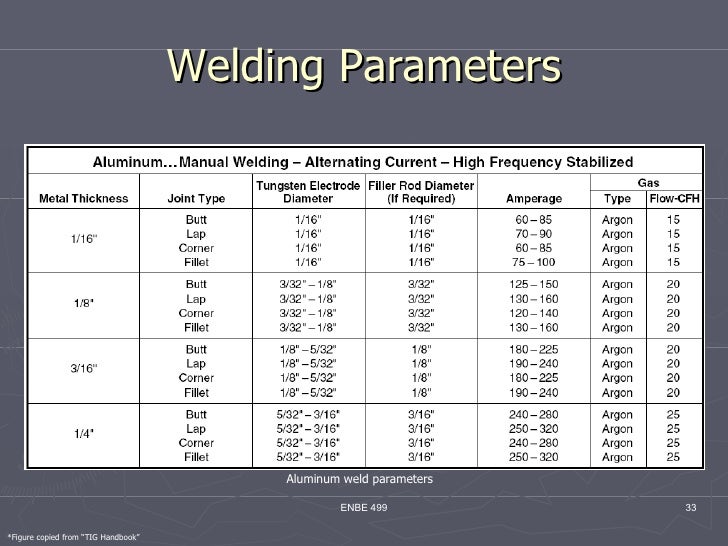

You can use the tungsten inert gas (tig) and metal inert gas (mig). You can ask your welding supplier for recommendations or if you have a mig welder that has a electrode wire and gas selection chart inside.

How To Set Up a MIG Welder Welder Settings, Gasses and

We recommend that you always fit a teflon wire liner;

How to weld stainless steel with a mig welder. The bead will not look great and have somewhat lower corrosion resistance. You’ll use welding wire that matches the type of stainless steel you’re welding. You should keep magnets near you if you start to weld from the header.

This will ensure good wire feed as well as preventing wire contamination. If you’re tig welding steel metals using thin sheets, concentrate the tungsten at the weld seam. Mig welding has a ton of applications, and each comes out with exceptional results.

But there is more you need to know, so continue reading! Mig welding sheet metal efficiently involves obtaining good fusion while simultaneously controlling: These stainless gas mixes are.

How to mig weld stainless steel? Mig welder setting for stainless and most nickel based alloys are very similar. You can also use a stainless gas mix such as the boc’s stainshield range of helium, carbon dioxide, and argon.

And if you’re prepared to weld stainless steel the normal way. Or stainless steel flux core wire. You should use 400 series sheets of steel because most stainless exhausts are made of 304 stainless.

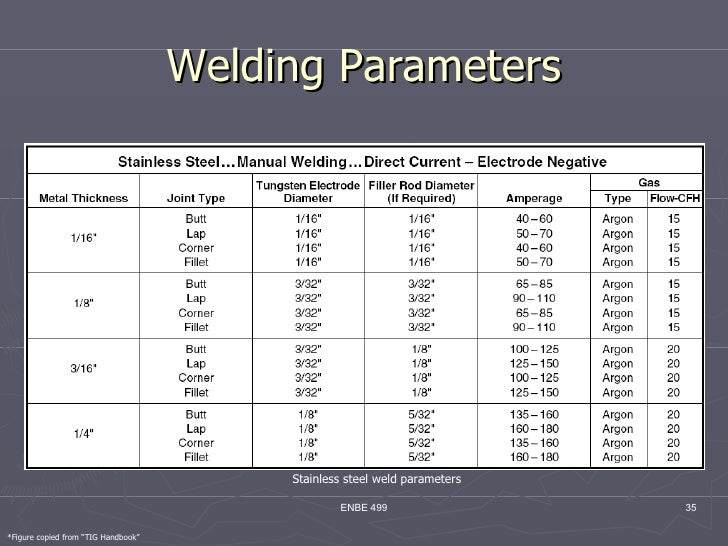

The most common electrode to weld stainless steel is the er308 l and the gas type is c2 or 2% carbon dioxide and 89% argon. For perfect results, you have to. However, the mig welding process, which uses filler, is most preferred when welding stainless steel to dissimilar metals, such as mild steel.

Then the best way to weld stainless steel is to use stainless steel mig wire.this process consumes an argon rich shielding gas and a solid wire electrode.tips to get the best stainless steel for mig welding. Suppose you want to try alternative methods and determine what you are most comfortable with. The answer to your first question is yes, you can mig weld thin gauge stainless steel in a short circuit mode with compact type 120v or 230v input power mig welders (see example in figure 1).the machine would have the same amperage and resulting material thickness capability with stainless steel as it does with carbon steel.

How to tig weld stainless steel: This process also uses shielding gas against contamination but you can weld thinner metals more efficiently with it. Pulse mig welding stainless steel

If you’re lost when it comes to mig welding steel, then it’s a must you get access to correct facts. The most common gas and electrodes to use for mig stainless steel welding. Stargon vs is a blend of 82% argon, 8% co2, and 10% helium.

Your welder should be set to direct current (dc) positive (+) to create a reaction between your feeder, wire, and steel surface. If you already have some experience in the world of welding, you should be completely capable of mig weld stainless steel, even with a regular hobby welding machine. Some basic approaches used by.

Use stainless steel mig wire. The spray transfer method involves spraying small droplets of molten metal from the electrode into the weld joint. Then, grind it at an angle parallel to the length.

When mig welding stainless steel, the correct choice of gas matters a lot, you can use pure argon or a blend of argon and other minor gases. You can use gasless or the type that needs a shielding gas. After all, you’re keen on getting the best welds for your stainless steel.

Firstly, as with any welding process, make sure your mig welding machine is set up correctly for welding stainless steel. Here are some factors and best practices to keep in mind when welding stainless steel with a mig welder: Don’t use carbon if you’re mig welding your stainless steel;

This is basically a common and unique process for joining stainless steel. Create a stable base a common practice of professional mig welders consists of preparing a stable base to prevent the workpiece from moving and. How to set your mig welder in joining stainless steel tune your welder’s polarity.

Then the best way to weld stainless steel is to use stainless steel mig wire. That is the gas i always have hooked up to my mig machine, so if i need to do a stainless mig weld, i just have to switch out the wire and that's it. So, that’s it about welding stainless steel to mild steel.

But some welders ask whether mig welding stainless steel with argon is possible. In fact, for some, it is the only way. Just make sure you use the right gas mixture, wire, and tweak the voltage little higher than you.

You may use a similar metal for welding. This includes your mig welder (complete with your welding gun, earth clamp, and spare parts such as nozzle tips) welding helmet, leather gloves, and fireproof covered clothing.

Carbon Steel Pipe MIG Welding www.pendarvismanufacturing