Here are some expenses cutting companies face when using waterjet cutters that will likely factor into your project quote: For operating cost, when you take into consideration the materials used for each machine, plasma will again score the lowest price with waterjet being the most expensive.

Schematic Diagram Of A Waterjet Cutting And B Abrasive Water Injection Download Scientific Diagram

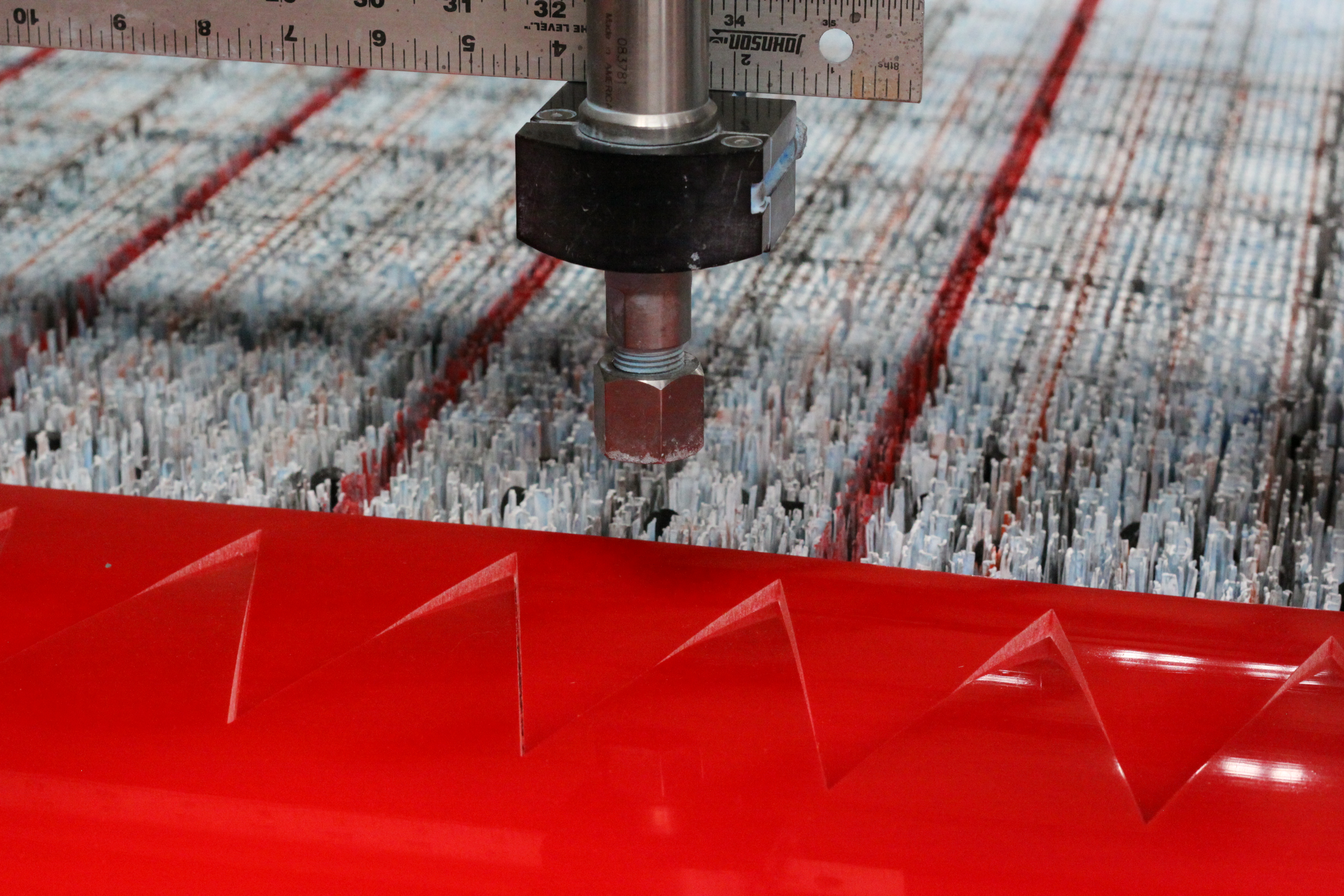

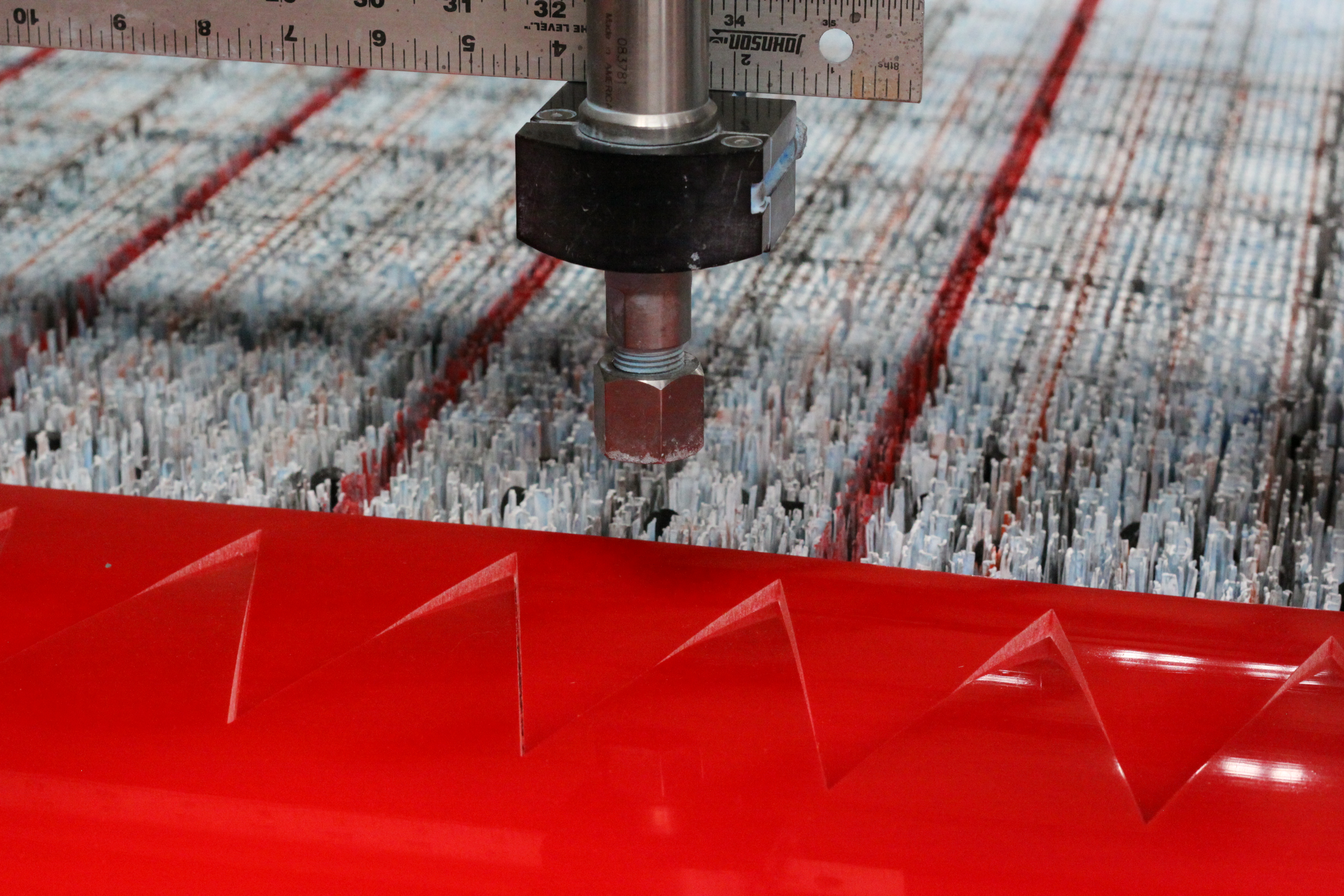

Waterjet cutting is to use high pressure water to cut or profiling steels and especially for highly brittle materials.

Is waterjet cutting expensive. Experience has shown that the hardness of the garnet often causes damage to expensive cutting. When you request to use a waterjet you are going to have to pay for more than just time occupying and utilizing the machine. Uniformity of material is not important.

Consumable materials such as water, fuel, and abrasive material also add to the overall expense. Waterjets make their own pierce holes. Laser cutting can sometimes leave a few burrs on the cut surfaces of the components.

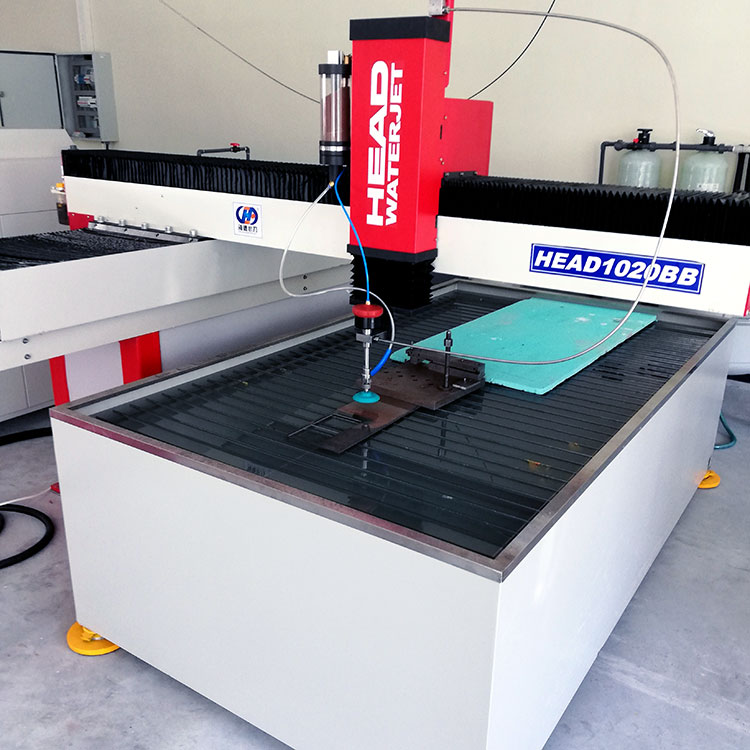

Is water jet cutting expensive? Regarding purchasing cost, a plasma cutting is the most cost effective while the laserjet is the most expensive. Machine itself is expensive and also the consumable for running the water jet is expensive.

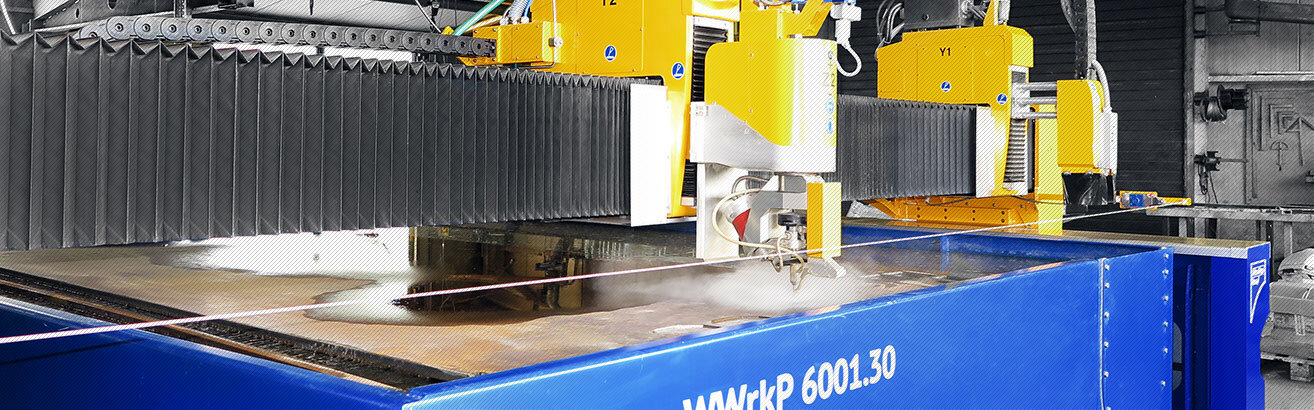

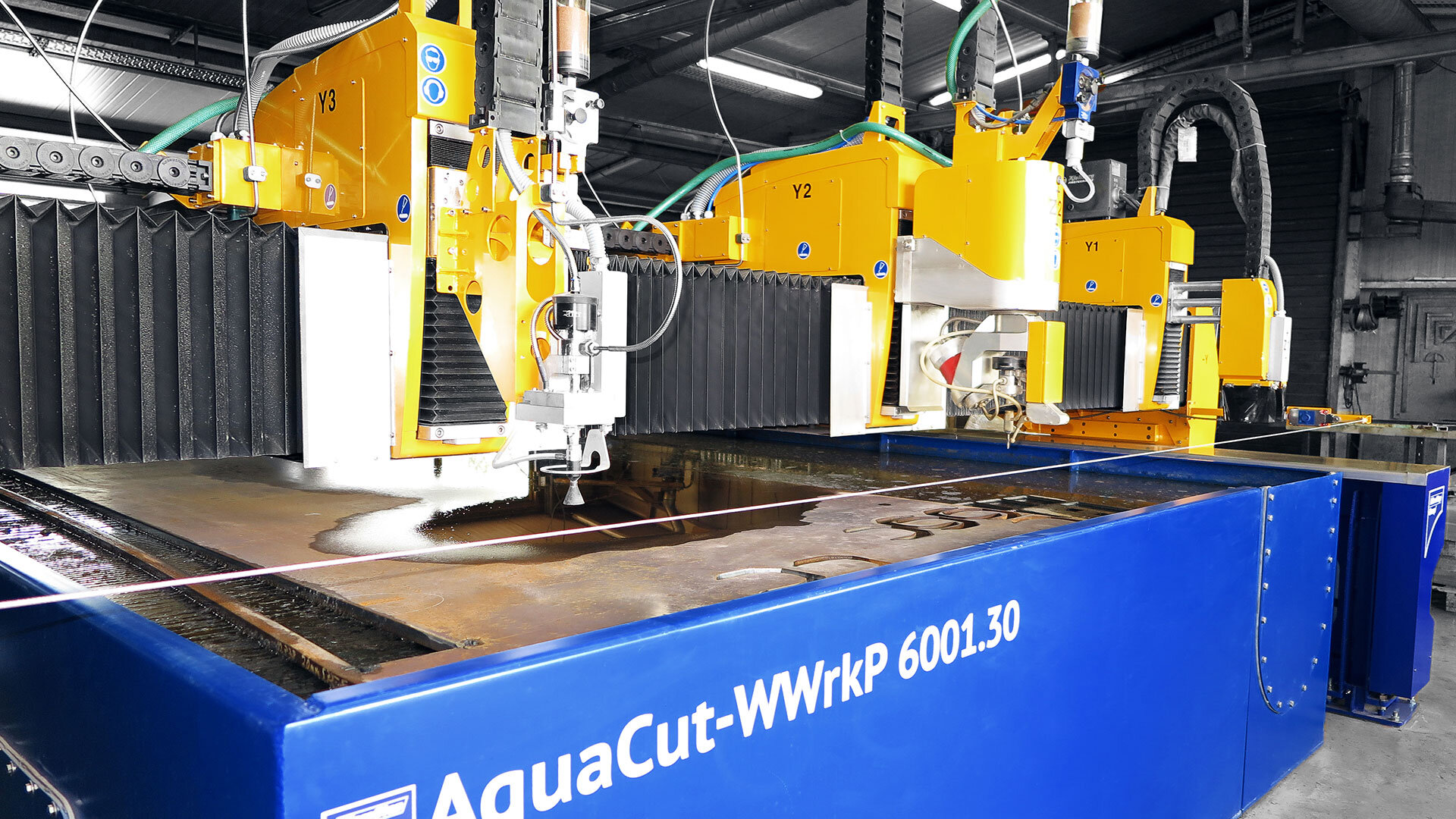

Much more cost efficient, edm is more expensive not only compared to waterjet, but to milling or turning as well. The cost of a plasma cutter can range from 15,000 usd to 300,000 usd. The cutting table is also the most expensive part of the entire waterjet machine.

Waterjet cutting costs depend on a lot of things. Waterjet cutting is a cutting procedure that has applications in various industries. Waterjet cutting machines are expensive to purchase, operate, and maintain.

It delivers smooth and precise cuts through the mechanical sawing action. Abrasive materials turn out to be the most expensive factor. Waterjet can also be used on laminated material.

For waterjet cutters, the operating costs depend on the cost of electricity, consumables, and abrasive material. For higher quantity runs, this process is generally more accurate and less expensive than normal waterjet cutting. Waterjet cutting machines are expensive to purchase, operate, and maintain.

Yes, waterjet cutting cost is high, but not to the extent of being unbearable. The price of the installation may vary depending on how many pumps. Waterjet is usually considered to be the most expensive, typically estimated at about $30/hour.

Abrasive jet machining is widely popular in industries such as the automotive, aerospace, medical and glass to create precision parts from virtually any material. There’s the cost of paying an operator. Waterjet cutting costs about $30 per hour, with abrasives making up about 75% of the cost.

Can work with more materials, unlike edm that can only machine conductive materials. For many years this kind of work was don e with garnet or other expensive abrasives. When you request to use a waterjet you are going to have to pay for more than just time occupying and utilizing the machine.

At the extremely high pressures used in waterjet cutting—60,000 psi or higher—component life can be problematic. If you have a project that requires small parts cutting or high precision cutting and you want to limit the need for a secondary finish, you can opt for a waterjet. For a waterjet cutter, the price is between 100,000 usd to 350,000 usd.

How accurate is waterjet cutting? The components then require deburring for optimal smoothness, functionality and safety. However, purchasing this cutter might be.

There are different consumables, different power requirements, cost of water, and most importantly, the cost of abrasive. The abrasive called as garnit is expensive and moreover the machine gets really messy after use. Relatively speaking, a water jet cutting process is highly accurate.

The cost to operate a waterjet is a common question, as people struggle to understand the difference between running a typical plasma cutting machine and a waterjet cutter. Plasma operating cost would again be the lowest, and is typically estimated at approximately $15/hour. Garnet are small grain like abrasive that are mixed in the water and are used for cutting action.

the abrasive is mixed with water under very high pressure to cut heavy steel structures. However, most of the plasma cutters cost below 100,000 usd. Advantages of waterjet cutting over edm:

The work they do often involves underwater abrasive waterjet cutting. The cost of laser would be slightly higher, typically estimated at around $20/hour. That’s the raw expense alone.

This is a versatile process in that it cuts through almost every material. This is because waterjet can cut stainless steel one minute and plastic the next. This is especially true of the waterjet pump, since that is the source of the high pressure water.

The initial purchase cost for plasma cutters is the lowest compared to waterjet and laser cutters.

Waterjet Cutting Info On Waterjet Technology

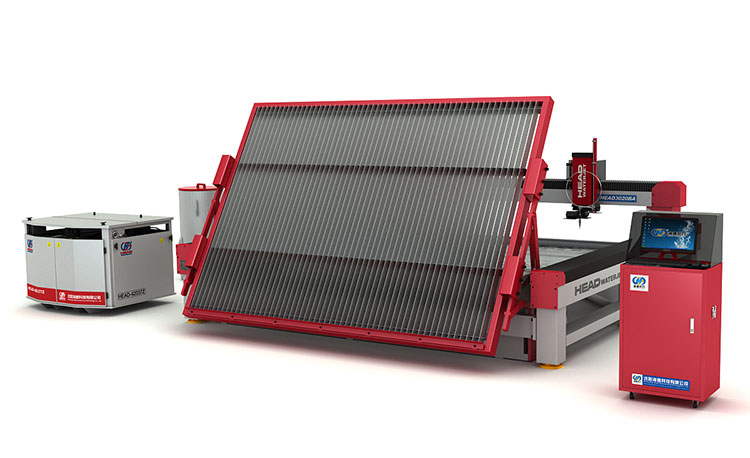

Small Cnc Mini Low Cost Water Jet Cutter From China Manufacturer – Headwaterjet

Abrasive Water Jet Cutting Machine – Accurl

What Is The Cost Of A Cnc Plasma Cutting Machine – Huafei Cnc

Shandong Wamit Cnc Technology Co Ltd Waterjet Cutting Machine Factory – Home Facebook

How Much Does Waterjet Cutting Cost

Abrasive Vs Pure Water Jet Cutting A Complete Comparison

3 Axis Waterjet Cutting Machine Metal Water Jet Cutter – Buy Water Cutting Machine Waterjetwaterjet Cutting Machine Metalwaterjet Cutting Machine Water Cutter Waterjet Cutting Machine Product On Alibabacom

Industrial Used 5 Axis Cnc Waterjet Cutting Machine China Manufacturer

Waterjet Cutter Water Jet Cnc Machine For Metal Stone Marble Cutting With 5 Axis Cutting Machine – Buy Water Jet Cutting Machinewaterjet Cutting Machinecutting Machine Product On Alibabacom

Marble And Glass Waterjet Cutting Machine Factory Prices From China Manufacturer – Headwaterjet

Waterjet Cutting Info On Waterjet Technology

How Much Does Waterjet Cutting Cost Same Waterjet

Teach You How To Use The Waterjet Cutting Machine Correctly

Watch The Diy Homemade Cheap Waterjet Cutter Machine Build Video Homemade Baby Gifts Diy Videos Water Jet

Waterjet Cutting The Ultimate Guide Machinemfg

Waterjet Cost What Factors Influence Waterjet Cutting Costs Rapiddirect