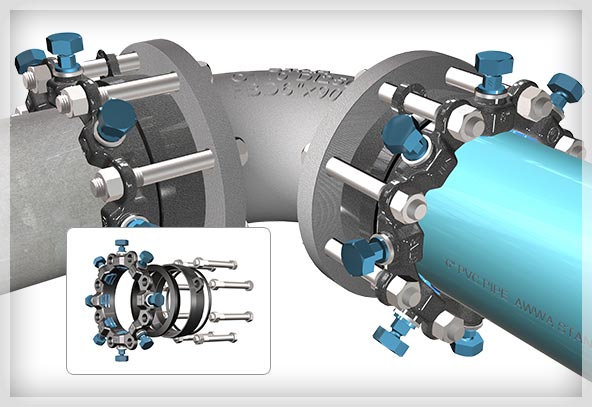

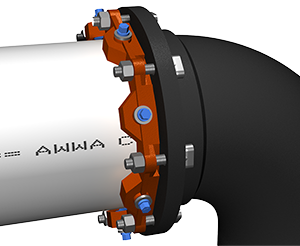

The principle of anchoring joints is to reduce the potential for the joint to separate. This will cause the steel teeth to grip the spigot of the pipe preventing the joint from separating.

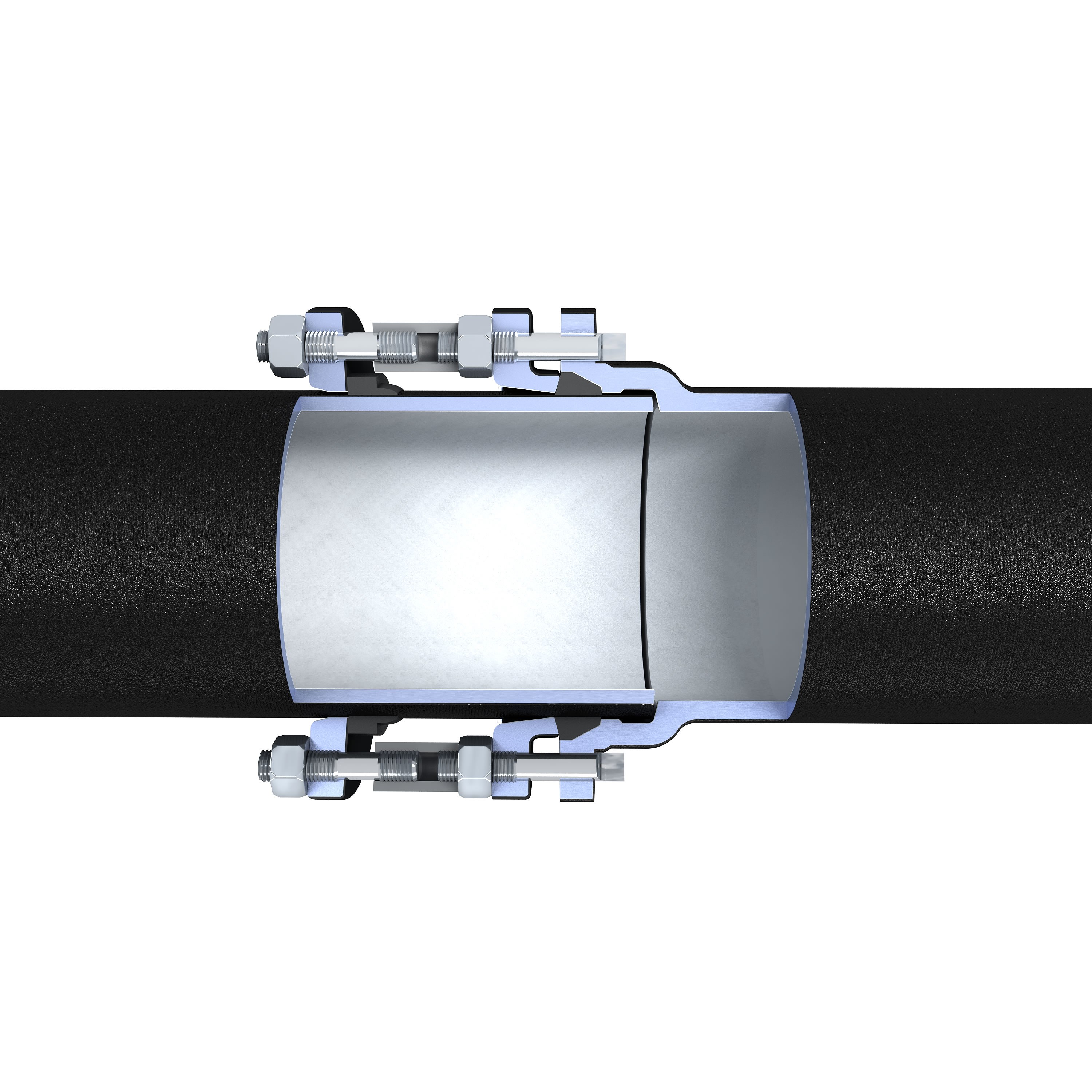

Geoflex Sliding Flexible And Extendible Fitting For Pipeline Protection

Where bolt holes are required to straddle the centerline of the fitting, this must be specified by the purchaser.

Mechanical joint fittings deflection. Mechanical joint flanges can normally Mechanical joint pipe is ul listed and fm approved. This accommodates some misalignment of the two elements connected by the mechanical joint due to earth settling, or other installation issues while maintaining a seal under pressure.

The water supplier should have standard details that would cover almost all common situations (tees, valves, bends, hydrants etc.). Evenly into the gasket recess. Tr flex restrained joint fittings;

Making a mechanical joint to each pipe. Orientation of bolt holes in mechanical joint fittings with respect to any centerline* is not fixed. • maximum allowable deflection for mj joint on a full length pipe is as mentioned below:

• maximum allowable deflection for mj joint on a full length pipe is as mentioned below: The available deflection in tr flex® restrained fittings as compared to the average amount of available deflection in mj fittings with wedge actions restraints is shown in the chart below: Mechanical joint fittings are available as full body c110 or compact body c153.

Df series deflection fittings compensate any directional movement between two conduit joints. For allowable joint deflection of mechanical joints see section 2. The mechanical joint system is designed for deflection as well as expansion and contraction within the piping system.

Welded outlets for ductile iron pipe; Used to provide offset, deflection and restraint for systems with misaligned flanges. Tr flex and hp lok telescoping sleeves

Make deflection after joint assembly but before tightening bolts. It is rated for a water working pressure of up to 350 psi. These fittings can withstand sporadic vibrations channeled by rotating equipment or vehicular traffic.

R y z mj mjxpe* mjxflg *2 2.25 3.25. Joint deflection to the maximum shown above may be made after assembly but before tightening bolts. The mechanical joint is used mainly with fittings rather than pipe.

Proper actuation of the gripping wedges shall be ensured with torque limiting twist off nuts. • in accordance with ansi/awwa c153/a21.53. This joint is designed to provide up to 15° joint deflection for subaqueous or other difficult installations.

• in accordance with ansi / awwa c110/a21.10. Insert bolts and hand tighten nuts. Mechanical joint is flexible, with the amount of deflection dependent on pipe diameter (table 2 and figure 2).

The mechanical joint is based on the stuffing box principle and consists of a bell with a flange The maximum deflection angle in table 5.0 is used for design purposes, and is based on eighty percent (80%) of the maximum Mechanical joint restraint shall require conventional tools and installation procedures per awwa c600, while retaining full mechanical joint deflection during assembly.

Keep the joint straight during assembly. The df series allows for a ¾” contraction and extension movement as well as a 30° angular deflection to any direction and still maintain Engineers for some of the world’s tallest buildings have used grooved mechanical piping systems to meet their deflection needs.

Deflections), for mechanical joint, the allowable joint deflection is 2 24' on each bell joint of the fitting. Sigma pipeline solutions offer two types of end restraint. Or mechanical joint fittings, currently make up the vast majority of ductile iron pipelines being installed for underground service.

Push the gland toward the socket and center it around the pipe with the gland lip against the gasket. Mechanical joints allow for some deflection of the joint. Joins plain end pipe to flanged fittings without threading or.

(1) for maximum joint deflections for full length restrained mechanical joint pipe with wedge action restraining glands, see table 5.0. Up to the maximum rating of the flange. Eral deflection and allows expansion and contraction of the line without leakage.

It is a type of compression joint designed for underground connection for pipe, valves and fittings. Approvals mechanical joint restraints shall be listed by underwriters laboratories in

Express Joint Fittingsex Syi Pipeline Corporation

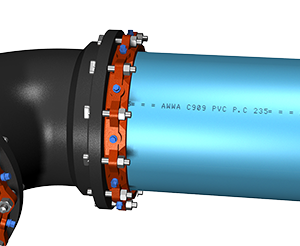

Ductile Iron Di Wide Range Flexible Quick Din Pn10 Universal Flange Adaptor For Pvc Pipe – Buy Carbon Steel Pipe Joint Ductile Cast Iron Quick Restrained Flange Adapterruntaida High Quality Carbon Steel

Ebaa Iron Inc – Leaders In Pipe Joint Restraint And Flexible Expansion Joints

Ebaa Iron Inc – Leaders In Pipe Joint Restraint And Flexible Expansion Joints

Ebaa Iron Inc – Leaders In Pipe Joint Restraint And Flexible Expansion Joints

Star Pipe Products – Ductile Iron Pipe Fittings Joint Restraints And More

Ebaa Iron Inc – Leaders In Pipe Joint Restraint And Flexible Expansion Joints

Mechanical Joint Fittings Us Pipe

Ebaa Iron Inc – Leaders In Pipe Joint Restraint And Flexible Expansion Joints

Ebaa Iron Inc – Leaders In Pipe Joint Restraint And Flexible Expansion Joints

Mechanical Joint Fittings Us Pipe

Mechanical Joint Fittings Us Pipe

China Ductile Iron Ex Express Joint Pipe Fittings – China Di Express Socket Mechanical Mj Joint Pipe Fitti Ductile Iron Express Joint Fitting

Tr Flex Versus Mechanical Joint – Why Tr Flex Fittings Are The Smart Choice – Mcwane Ductile – Iron Strong