Originally linseed oil was boiled in a vacuum to remove molecules of oxygen and breakdown its food components, principally fatty acids. Saturate the wood, especially the end grain.

Oil Finish Comparison woodworking YouTube

Linseed products suitable for wood finishing on the market today are sold as “boiled linseed oil” or “purified linseed oil”.

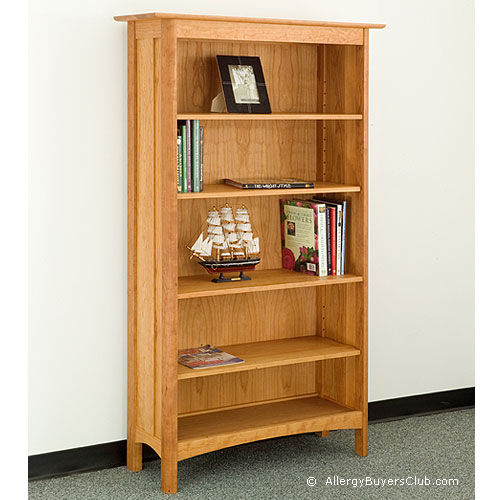

Wood floor linseed oil finish. When linseed oil is applied, it gives a golden hue to the wood, which slowly turns amber as it ages. Linseed oil is a penetrating finish on hardwood floors that does not form a sealant on the wood like polyurethane, but instead acts as a stain that enhances the look of your floors. For a finish i have chosen linseed oil for two major reasons.

Also, how do you finish oil on wood? I have a 60 year old maple floor that i have stripped down and sanded. Linseed oil (aka flaxseed oil, or flax oil) is also a good choice, for a different reason.

Linseed oil and wood oils are different from more common finishes such as polyurethane in that they soak into the wood rather than sit on the top. Linseed oil is a product extracted from dried linseed. Oil finished floors are excellent for bringing out the natural beauty of your selected wood specie.

Linseed oil, also known as flaxseed oil, is one of the most popular wood finishes in the world. Here’s one of our favorites. Many hardwood floor professionals are fond of the easy application for penetrating oil systems.

Click to see full answer. I've done a little reading and it seems that the benefits are 1) a more natural looking floor, and 2) i can 'spruce' the floors up myself. Apply a good coat of the linseed oil/wax finish.

The difference | oiled finish hardwood floors matte finish and easy to maintain. Made from the dried seeds of the flax plant. A finish like polyurethane forms a protective.

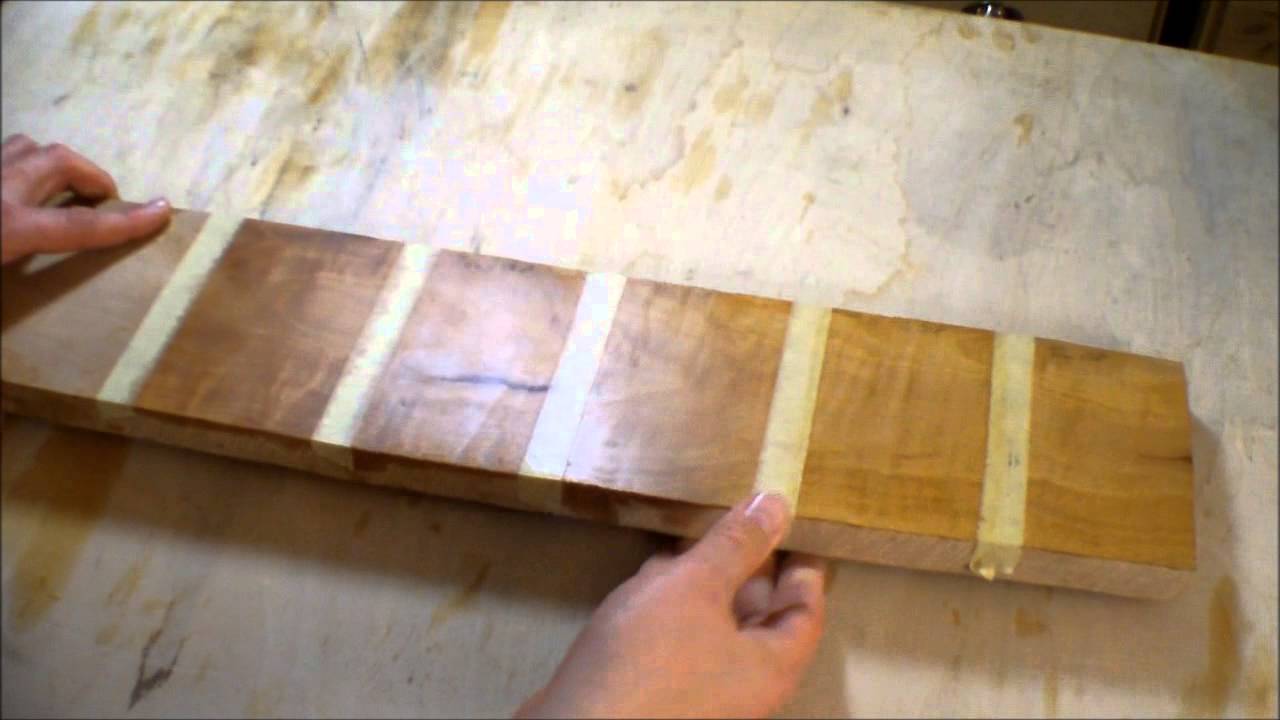

After 10 minutes, wipe off everything that has not been absorbed. Unlike poly finished floors, oiled. Make sure all the show surfaces are prepared to the same level of refinement.

Pure linseed oil isn't practical for wood finishing because it does not dry. Get the whole chair, box or shelving unit covered with the stuff. Usually giving it about 24 hrs between coats, you’ll build up between 3 and 6 coats of oil depending on how thirsty the wood is.

The boiled product penetrates into the wood's grain, which accentuates the pattern. Originally linseed oil was boiled in a vacuum to remove molecules of oxygen and breakdown its food components, principally fatty acids. To apply an oil finish, flood it onto the wood, adding extra to keep the surface wet in areas where the oil is quickly absorbed.

Using tung or linseed oil as a floor finish instead of poly. While boiled linseed oil is the more preferred form for use as a finish. With polyurethane there is concern about lap lines, feathering, and streaking in an application that can result in a poor looking finish.

Created in ancient times, it is now used in the maintenance of exterior wood (garden sheds, siding, wooden structures) and interior wood (parquet, furniture) and is the most popular oil for finishing woodwork around the world. The wood floor finished in this style system also feels warmer under foot. Wood floor linseed oil finish.

I was speaking with a sales rep’ at carlisle's today, and he suggested that i put tung oil on my floors instead of poly. Prepare the raw wood just like you would for any clear finish. Made from the dried seeds of the flax plant, linseed oil is processed to speed up the drying time, producing boiled linseed oil.

How we finished our yellow pine floors (without poly

Linoleum Flooring Not just for Grandma's House? Angie's

Mahogany (Sapele) built in furniture DIY Wardrobes

Artisans of the Valley Educational Services Tung Oil